LOGISTICS OPTIMIZATION

— ESTAFETA ALGORITHMS

the Challenge

Estafeta was facing two obstacles: having inactive vehicles and a lack of estimated arrival times for customers’ shipments. That led to the challenge of optimizing their logistics area.

the Proposal

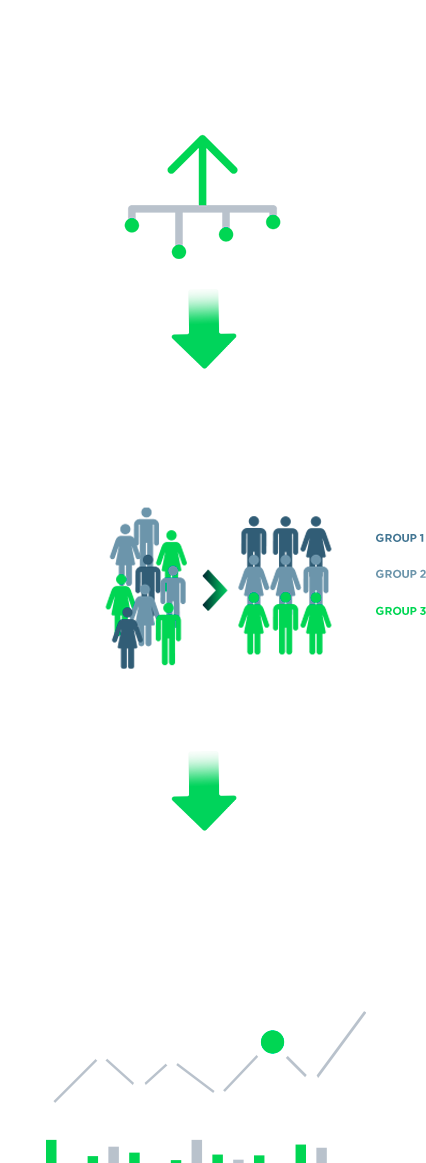

After several meetings with the team, we agreed to develop an optimization algorithm to reduce delivery times, minimize kilometers traveled, avoid high-risk areas, balance the use of the fleet and increase the number of daily deliveries.

We collected and grouped past company data , including the number of vehicles and their characteristics, types of goods to be transported, delivery times, and geographic data. This allowed us to reduce planning time and increased the number of deliveries.

THE IMPACT

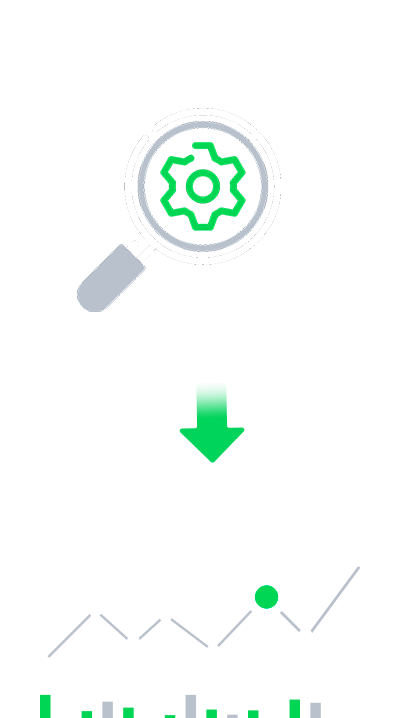

The company reduced their planning costs by 12% and budgets by 7%. These improvements led to recurring month-over-month increases in the results.

Inmoove provided training to the client’s editorial and administrative teams with data that was both actionable and easy to use, enabling them to make informed decisions independently.

The company reduced their planning costs by 12% and budgets by 7%. These improvements led to recurring month-over-month increases in the results.

Inmoove provided training to the client’s editorial and administrative teams with data that was both actionable and easy to use, enabling them to make informed decisions independently.